An ideal method for Economic, Accurate & Reliable Dispensing

An ideal method for Economic, Accurate & Reliable Dispensing

• Electronically Controlled

• Extremely Accurate

• Easy Installation and Operation

• Economical Solution

Scienco® FloCRON® Liquid Dispensing Injection System provides economic, accurate and reliable dispensing equipment for industrial and food processing markets. The Scienco® FloCRON® is designed to dispense a pre-set amount of viscous liquid into individual cans, jars, pouches, or bottles during the filling process. Scienco® FloCRON® applications are primarily determined by line speed, container opening, amount of liquid dispensed and product viscosity.

![]() Scienco® FloCRON® Liquid Injection Brochure

Scienco® FloCRON® Liquid Injection Brochure

About the Liquid Injection System

Ideal uses for dispensing liquids: water / brine solutions, liquid citric acid, liquid calcium chloride, variety of oils, variety of sauces, and more!

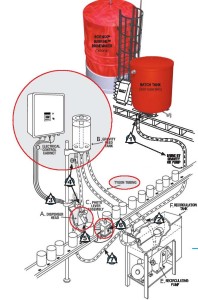

The basic system consists of the following; other items are optional or sold separately:

A.) Dispenser Head

B.) Gravity Feed Tank

C.) Photo Lever Assembly (other trigger options are available)

D.) Electrical Control Cabinet

E.) Recirculation Pump

F.) Recirculation Tank

The Scienco® FloCRON® control cabinet can operate two dispensing heads on the line at the same time to double the amount of product being dispensed into the container, ideal for larger or over-sized containers. The FloCRON® system can handle line speeds of up to 400 cans per minute. To achieve greater line speeds, split the lines to use multiple FloCRON® systems and then merge the lines back together.

The Scienco® FloCRON® is a constant-flow, closed loop system designed to dispense low viscosity materials; ideal for: water/brine solutions, liquid citric acid, liquid calcium chloride, variety of oils, sauces, and more!

HOW IT WORKS: Liquid is delivered from a batching tank or brinemaker (SciBRINE®) to a recirculation tank complete with a shut-off valve and float to control the flow.

HOW IT WORKS: Liquid is delivered from a batching tank or brinemaker (SciBRINE®) to a recirculation tank complete with a shut-off valve and float to control the flow.

- Liquid is then pumped from the recirculation tank to the gravity feed tank. Then the liquid flows to the dispensing head (2 heads available: E3-Normal and A4-High Heat), where the deflector assembly diverts the liquid into the container when the head is triggered.

- The flow of liquid is controlled by a valve on the gravity feed tank and also a nozzle in the dispensing head.

- The Photo Lever Assembly is shown, but other trigger sensor options are available, such as a proximity switch. This triggers the feed with the dispensing head.

- Liquid that was not directed into the container flows back to the recirculation tank and the process is repeated.

4 nozzle sizes are available to regulate flow from the head (consult factory for nozzle recommendations). Available Models:

FloCRON® Model E-3 – The E-3 model utilizes an electro-mechanical dispensing head. The E-3 uses either 12 or 24 volt coil (depending on the control cabinet selected) to provide electricity to the rotary solenoid.

FloCRON® Model A-4 – The A-4 model utilizes an air-operated dispensing head. It is recommended for applications when product temperature is over 180 degrees F.

FloCRON® Model LV – The LV (Large Volume) model is an air-operated dispensing head used in high-volume, low-line-speed applications. A large poly tank is typically used in place of the gravity feed tank and recirculation is typically not required.

FloCRON® TC-3 Control Cabinet – The TC-3 incorporates digital control circuitry that gives the FloCRON System a quicker response time that increases the line speed capability. The new cabinet also has a built in counter that counts each time the head is activated. This has proven a plus with quality control.