We introduced the BioBarrier® MarineMBR™ Membrane BioReactor for the marine marketplace. Just like our land-based MBR applications, this NSF/ANSI (40 class 1, 245 Nitrogen Reduction, and 350 Water Reuse), EN12566-3, USCG, and IMO, certified MBR system removes 99.9% of the contaminants from domestic and high strength wastewater flows.

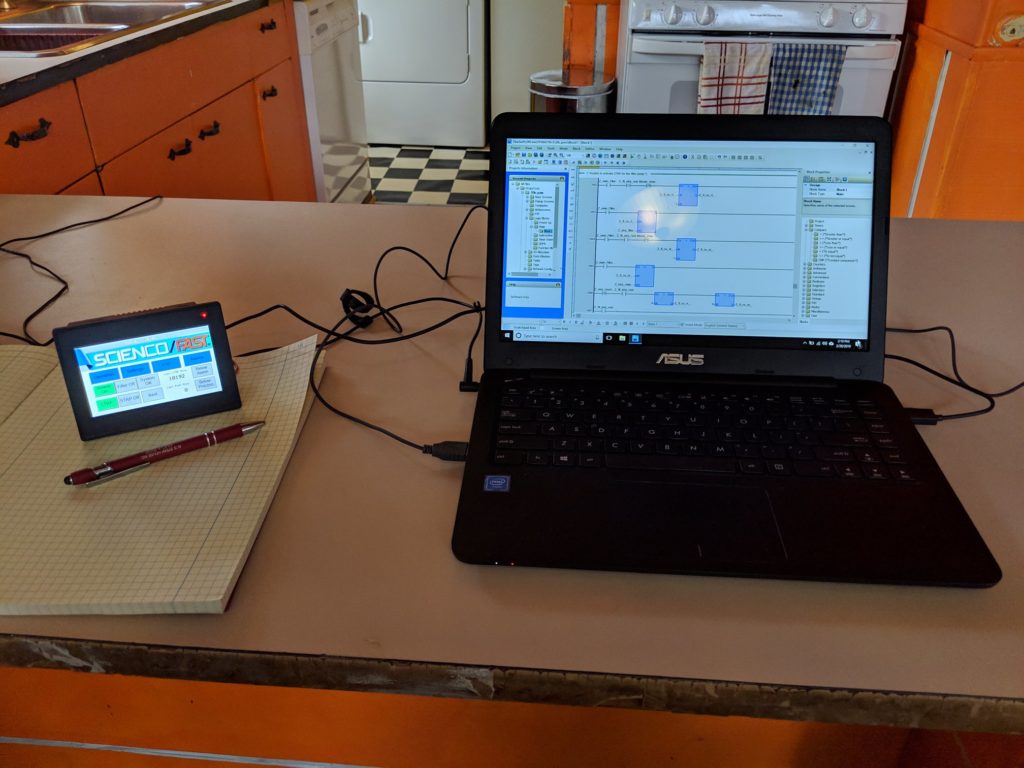

To assure consistent effluent quality, the BioBarrier® MarineMBR™ (land-based version was the first system certified for water reuse (NSF/ANSI Std 350, class R) for total blackwater and greywater recycling onboard a vessel adheres to strict water quality guidelines. Each system operates automatically and is controlled by a three level float switch and timing relays in the control cabinet:

- BOD less than 5 mg/L

- TSS less than 2 mg/L

- Turbidity less than 0.2 NTU

- Fecal coliform less than 200 CFU/100 mL (without disinfection)

How it Installs

How it Installs

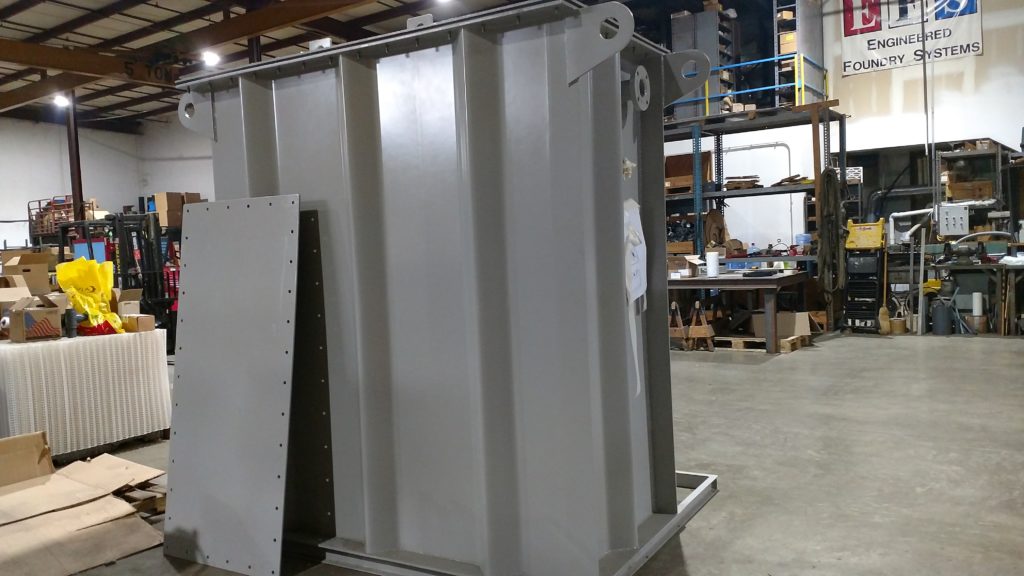

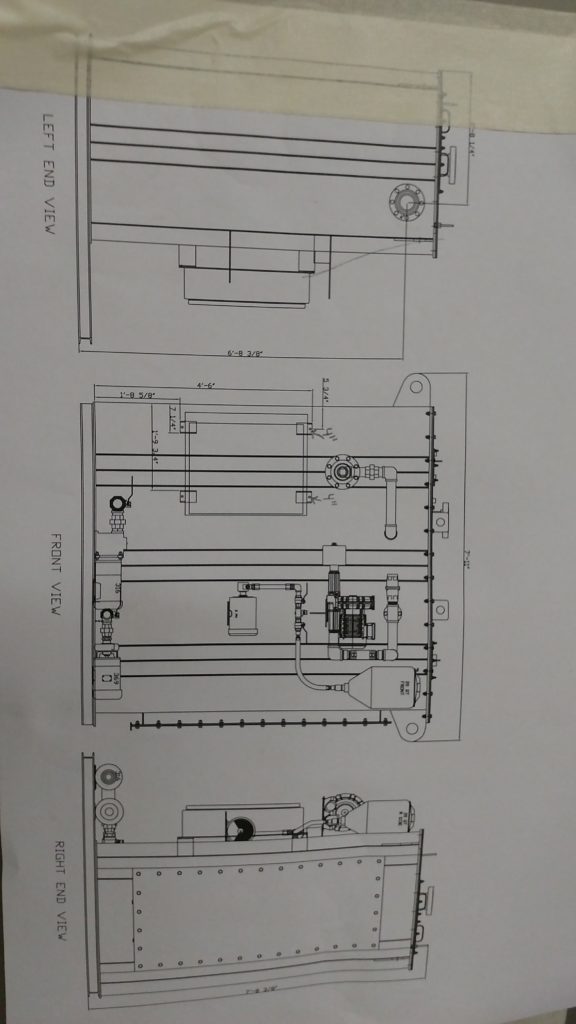

BioBarrier® membrane bioreactors are engineered to treat all sources of blackwater and greywater in varying strengths and dependent on daily wastewater flow. The Scienco/FAST custom MarineMBR™ steel tank provides access for maintenance and removal of the membranes for deep cleaning or replacement. As well as the maintenance on the filtrate pumps and easy to access blower(s), while keeping as much of the equipment below deck and out of sight. All penetrations for air lines, filtrate outflow and electric cables are installed below the main deck. A submersible pump is mounted on the membrane module housing and used as the filtrate pump.

Finding the Right Size

Finding the Right Size

It is recommended to check what local regulations are required in case additional information is needed.

BioBarrier® MarineMBR™ Based on GPD [L/D] and Sewage Factors

Contact Factory for sizing