A simple and reliable method of dealing with accumulated sewage sludge on vessels and offshore platforms. FAST® is the easy way to deal with sludge.

A standard MarineFAST® unit meeting MEPC.159(55) or providing secondary treatment incorporates about one (1) month of internal sludge storage. However, if you employ the next sized FAST unit, internal sludge storage can be increased to 3 months, without any additional equipment. For larger MarineFAST units, the DV-Series, we offer the BMS system below:

Description

Designed for larger commercial vessels and offshore structures, the MarineFAST® systems and the MarineFAST® HS-MSD™ (high strength marine sanitation devices) Systems are completely assembled, wired and tested. Ships and platforms must be able carry their own potable water supply, with water reuse capabilities, this supply can be utilized more efficiently. Because of this water conservation, certification tests require concentrated sewage. The majority of sewage in a MarineFAST unit is pretty concentrated and stored appropriately. The MarineFAST MSD is also designed for the higher hydraulic loading associated with more dilute sewage.

The unique design provides the greatest possible flexibility in locating and installing the system aboard ship. This flexible design offers the ultimate in strength, corrosion resistance and performance. Available in bolt-together modular form for installation aboard existing vessels, such as ferries, off-shore platforms and ore carriers. For longer periods, the MarineFAST BMS provides an aerobic sludge digester with long-term internal storage. Operation is completely automatic and hands-free.

In the MarineFAST BMS tank, the sludge is completely enclosed in tanks and piping – no need for personnel to come into contact with sewage or sewage sludge!

The MarineFAST BMS Reference Data provides instructions and examples for selecting a system plus dimensions, weights and other data. As a complete BioSolids (sludge) Management System:

- Reduces sludge volume by 65% compared with other systems.

- No strainers, filters, membranes or centrifuges – clogging is virtually impossible.

- Proper operation does not depend upon the skill of the operator.

- Does not affect the dimensions, weights or operation of the FAST® unit.

- Vents to weather through the FAST unit – no separate vent piping required.

MarineFAST® Sewage Treatment Systems are powerful, biological (aerobic digestion), flow-through discharge devices. All MarineFAST® (Fixed Activated Sludge Treatment) units are fully certified by US Coast Guard under U.S. and IMO regulations. Designed for virtually every type of vessels and offshore structures with head and/or galley facilities, the MarineFAST MSD and HS-MSD(TM) Series Systems are completely assembled, wired and tested in extreme conditions on their own foundation. Larger ships and platforms must be able carry their own potable water supply; and with water reuse capabilities, this supply can be utilized more efficiently. Because of this water conservation, certification tests require concentrated sewage and stored appropriately, such as from a MarineFAST unit. Designed for the higher hydraulic loading associated with more dilute sewage, the MarineFAST MSDs can last for the life of the vessel and beyond.

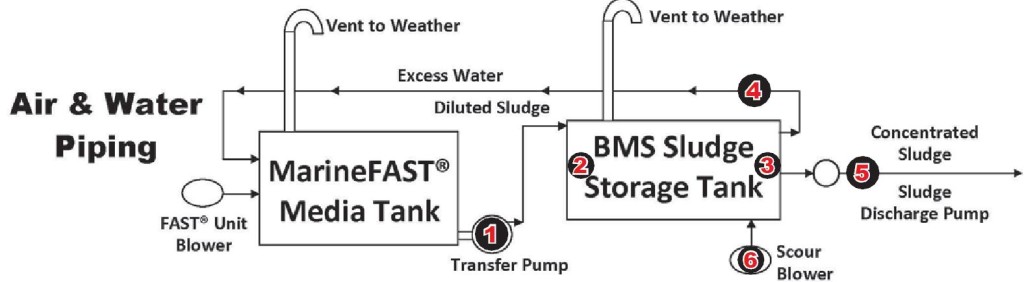

How It Works

1. The transfer pump automatically moves the sludge-water mixture from the FAST media tank to the BMS tank.

2. The sludge is aerobically digested during storage. Because of the long detention time in the digester, the sludge is substantially reduced in mass and volume.

3. A rising liquid level in the digester shuts off the blower and allows sludge to settle to the bottom of the tank. This permits excess water to be pumped back to the FAST media tank for treatment and legal discharge to the sea.

4. Alternating aerobic and anoxic states within the digester stabilizes pH, maintaining a healthy culture for efficient digestion of the sludge.

5. The sludge discharge pump can deliver the concentrated sludge to an OSV, to a larger tank provided by others or to an incinerator, whatever best fits the special requirements of the vessel or platform.

6. Aeration ensures that the entire contents are mixed, permitting the sludge discharge pump to empty the space efficient flat bottom tank.

Please see MarineFAST® BMS Reference Data for sizing.

Effluent Standards

EFFLUENT STANDARDS

Check which effluent requirements you must meet.

- USCG 33CFR159 Minimum Standards: 150 TSS, 200 fecal, certified by U.S. Coast Guard installed aboard vessels and not subject to effluent sampling in service not required by regulations.

- MEPC.159(55) – 25 BOD5, 35 TSS, 125 COD, 100 fecal effluent for USCG certified units and recommended for general marine use with 1 months internal sludge storage and dechlorination of effluent. All standard FAST units are also certified under MEPC.227(64).

- EPA VGP 2013 – Secondary treatment may be required for restricted waters, barges meeting local or harbor regulations, and offshore applications that are subject to state or other regulations. Applications requiring 85% removal, 30 BOD5, 30 TSS secondary treatment and 3 months internal sludge storage.

The LX-Series – This new economical and lightweight modular design is ideal for small commercial vessels. It is strong, corrosion resistant and will fit under the stairway of a tug engine room.

The M- & MX-Series – Modular steel units will handle crews of up to 60 persons and will fit into shaft alleys and other spaces with low headroom and restricted access. The MX are assembled versions of the M-Series, these compact package units are ideal for workboats, dredges, offshore vessels and structures, and other commercial vessels.

The DV-Series – For larger crews, these flexible designs offer the ultimate in strength, corrosion resistance and performance. They are available in bolt-together modular form for installation aboard existing vessels, such as ferries, off-shore platforms and ore carriers.

Technical Downloads

[/wptabcontent]MarineFAST® Product Brochures

- Scienco/FAST Corporate Overview

- MarineFAST® BMS Product Brochure

- MarineFAST® BMS Reference Data Sheet

- MarineFAST® BMS Design Specifications

MarineFAST® Sizing and Specifications

|

Why Scienco/FAST Systems…

MULTIPLE APPLICATIONS IN EVERYDAY SERVICE

With decades of proven results and more than 50,000 land/marine installations, FAST® systems have been used from harbor tugs to cruise ships and from single homes to small cities. The largest MarineFAST systems process more than 195,000 gpd (739 m3/d) and the largest land FAST systems process more than 1.5 mgpd (5,680 m3/d).

PROVEN TECHNOLOGY

With more third-party certifications, technology approvals, and awards, BioMicrobics, Scienco/FAST, and SeptiTech are known for its decentralized wastewater (total blackwater/greywater) treatment technologies. These systems have performed exceptionally well in achieving higher levels of nitrogen removal and optimal effluent quality with automated operation and energy-efficiency required in today’s standards and regulations. In addition, the treatment quality our expanded product offering can help meet most, if not all, onsite application goals.

SIMPLE PROCESS

Using ordinary pumps, blowers and controls already familiar to vessel personnel, the sophistication of the BMS component is inherent in the state of the art process and the know how needed to get maximum benefit from it.

OTHER BENEFITS

Aerobic process and ABS deep tank standards – no corrosion or terrible odors. All machinery, piping and controls meet USCG requirements for inspected vessels.