Advanced Wastewater Treatment Systems are rapidly becoming the standard type of treatment system on cruise ships. These systems typically consist of a multi-stage treatment process that includes filtration, biological treatment, and disinfection of wastewater prior to discharge.

Click HERE to download the MarineFAST® Operating Manual.

The M- & MX-Series – Modular steel units will handle crews of up to 60 persons and will fit into shaft alleys and other spaces with low headroom and restricted access. The MX are assembled versions of the M-Series, these compact package units are ideal for workboats, dredges, offshore vessels and structures, and other commercial vessels.

The M- & MX-Series – Modular steel units will handle crews of up to 60 persons and will fit into shaft alleys and other spaces with low headroom and restricted access. The MX are assembled versions of the M-Series, these compact package units are ideal for workboats, dredges, offshore vessels and structures, and other commercial vessels.

Description

A simple and reliable method of dealing with accumulated sewage sludge on vessels and offshore platforms. FAST® is the easy way to deal with sludge.

A standard MarineFAST® unit meeting MEPC.159(55) or providing secondary treatment incorporates about one (1) month of internal sludge storage. However, if you employ the next sized FAST unit, internal sludge storage  can be increased to 3 months, without any additional equipment.

can be increased to 3 months, without any additional equipment.

MarineFAST® M- & MX-Series Type II Marine Sanitation Devices (MSDs) to treat all blackwater and greywater generated on board. The MarineFAST® M- & MX-Series System were designed specifically for installation where space and access for installation are limited. Both the M-Series and MX-Series require no special training or expensive spare parts.The best part of all, they require no manual cleaning.

- Flow range: 200-1500 GPD (800-5700 LPD)

- Ideal where access can be extremely limited

M-Series – Use in low headroom installations and other installations where access to available space and the space itself are extremely limited. Each of the M-Series’ components can be located in different compartments or on different decks if necessary. Additionally, each M-Series component will pass through a standard watertight door without disassembly and is pre-assembled and tested at the factory.

MX-Series – (Assembled version of the M-Series) The MarineFAST® MX-Series combines the Media tank and Wet Well in a single compact weldment. Standard units are completely assembled, wired and tested at the factory before shipment.

MarineFAST® Systems are commonly referred to as a Type II (two) MSD biological (aerobic digestion) treatment system. The Type II MSD systems are powerful, flow-through discharge devices and tested in conditions described in 33 CFR 159.121. MarineFAST® Marine Sewage Treatment Marine and offshore sewage treatment systems built to handle extreme environments. All MarineFAST® (Fixed Activated Sludge Treatment) units are fully certified by US Coast Guard under U.S. and IMO regulations.

Effluent Standards

EFFLUENT STANDARDS

Check which effluent requirements you must meet.

- USCG 33CFR159 – Minimum 33CFR159 / MEPC.2(VI) standards for 150 TSS, 200 fecal, certified by U.S. Coast Guard installed aboard vessels and not subject to effluent sampling in service not required by regulations.

- MARPOL 2010 – 25 BOD5, 35 TSS, 125 COD, 100 fecal effluent for USCG certified units and recommended for general marine use with 2 months internal sludge storage and dechlorination of effluent. Secondary treatment may be required for restricted waters, barges meeting local or harbor regulations, and offshore applications that are subject to state or other regulations.

- USEPA Secondary Treatment – Applications requiring 85% removal, 30 BOD5, 30 TSS secondary treatment, 3 months internal sludge storage, and derate by 10% for dilute sewage.

Technical Downloads

MarineFAST® Product Brochures

- Scienco/FAST Corporate Overview

- MarineFAST® ALL SIZES Brochure

- MarineFAST® Operating Manual

- FAST® Design Guidelines

- M- Series Data Reference Sheet

MarineFAST® Sizing and Specifications

How It Works

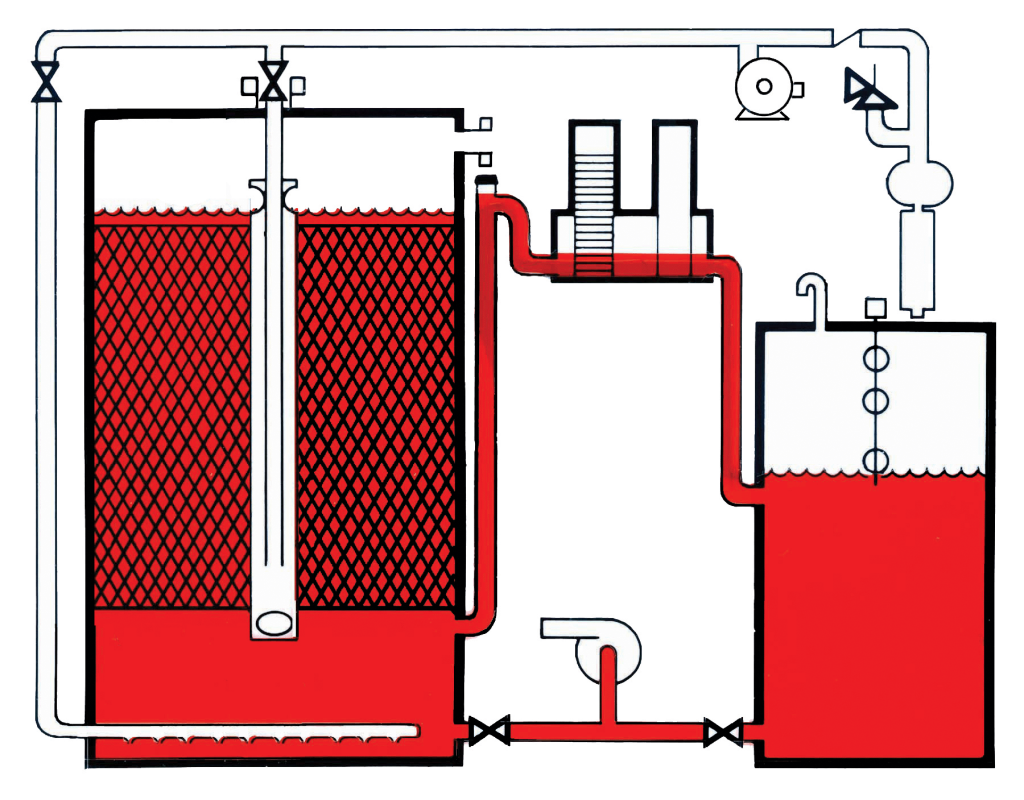

- Sewage enters the system. No need for a macerator or bar screen to clean or repair.

- Quiet, compact BLOWER provides air through the piping system that connects to the airlift inside the media tank.

- Aeration through the AIRLIFT circulates and aerates the tank contents to promote microorganisms present in sewage to grow and become fixed on Media to digest organic material. Media does not require replacement or cleaning.

- From center line SPILLOVER pipe, treated effluent passes through TABLET CHLORINATOR and dissolves chlorine tablet proportional to the flow rate. Other disinfection methods are available.

- Sized for peak flow periods, the Chlorine Contact Tank or WETWELL provides the chlorine enough time to disinfect treated effluent prior to discharge. Automatic Float Switches (shown in yellow) located in the center line of the tank gauge water levels for on/off operation.

- A submerged EFFLUENT PUMP in the wetwell transfers the treated effluent to discharge out of the tank. Other transfer options available.

Please see MarineFAST® Product Brochure for sizing and Reference Data.

Why Scienco/FAST Systems…

MULTIPLE APPLICATIONS IN EVERYDAY SERVICE

With decades of proven results and more than 50,000 land/marine installations, FAST® systems have been used from harbor tugs to cruise ships and from single homes to small cities. The largest MarineFAST systems process more than 195,000 gpd (739 m3/d) and the largest land FAST systems process more than 1.5 mgpd (5,680 m3/d).

PROVEN TECHNOLOGY

With more third-party certifications, technology approvals, and awards, BioMicrobics, Scienco/FAST, and SeptiTech are known for its decentralized wastewater (total blackwater/greywater) treatment technologies. These systems have performed exceptionally well in achieving higher levels of nitrogen removal and optimal effluent quality with automated operation and energy-efficiency required in today’s standards and regulations. In addition, the treatment quality our expanded product offering can help meet most, if not all, onsite application goals.

Fully certified by the US Coast Guard under 33 CFR Part 159 and IMO rules, FAST® (Fixed Activated Sludge Treatment) treatment systems can be found around the globe in offshore, municipal, industrial, commercial and residential applications. The reason for FAST’s success is its ability to provide years of reliable trouble-free service without adjustments or the need for a skilled operator.

SIMPLE PROCESS

Using ordinary pumps, blowers and controls already familiar to vessel personnel, the sophistication of the BMS component is inherent in the state of the art process and the know how needed to get maximum benefit from it.

OTHER BENEFITS

Aerobic process and ABS deep tank standards – no corrosion or terrible odors. All machinery, piping and controls meet USCG requirements for inspected vessels.

Also, FAST is already capable of meeting the next generation of sewage regulations. This protects you from changes in the regulations or from individual foreign or local regulations which exceed minimum USCG certification requirements.

Worldwide Service

With vessels circling the globe, service questions often arise. Service is available worldwide, with equipment manufactured in the United States, Canada and Australia.

For larger MarineFAST® Systems, check out the M- & MX-Series or DV-Series.