Upon submitting your inquiry, a member of our sales team or your local distributor will contact you about your project within 72 hours. If you would like to talk directly to a member of our sales team about a specific project, please call 1-314-756-9300.

Did You Know?

Did You Know?

FAST® processes raw, unscreened sewage as it is produced

FAST units are capable of handling any combination of blackwater, graywater, ground food waste, freshwater, seawater, vacuum toilets and conventional toilets. No macerators, grinders, pretreatment or flow equalization tanks are required.

Clogging in everyday operation is virtually impossible

The process is very turbulent and the airlifts used for oxygen transfer throw foreign objects to the sides of the tank where they will not interfere with the process. There are no moving parts in contact with sewage, no filters, membranes or fine pore aerators to blind or plug.

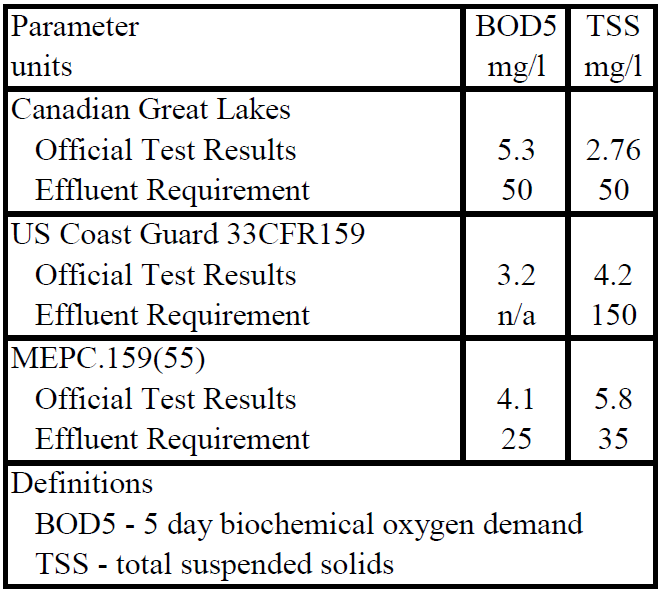

FAST effluent meets any known marine standard worldwide

FAST units provide outstanding effluent quality without any filters or membranes. Consider official testing under three separate regulations over a 33 year span and with standard production units:

FAST is not adversely affected by light loading

Many biological processes are upset by light loading. The only effect on FAST is that the effluent quality is even better.

FAST starts up in half the time

FAST starts up much faster than conventional suspended growth processes. Also, FAST is self-starting without powdered bacteria or activated sludge from another sewage treatment plant.

In the real world, all biological processes are upset from time to time. FAST handles these quickly and automatically and no operator intervention is required.

FAST produces the minimum amount of sludge possible

All processes capable of removing pollutants to meet MEPC.159(55), US EPA and other secondary effluent standards produce a residual sludge that requires separate disposal – that is, all processes that do not employ dilution to meet standards.

The FAST process supports a more complex microbial culture than conventional suspended growth systems. Segmented sludgeworms, insect larvae and other higher ordered organisms predate upon simpler microorganisms and reduce the mass rate of sludge accumulation by one-third or more.

At the same time, FAST sludge is heavier and more concentrated than that from suspended growth systems of all types (including MBR’s). In volumetric terms, the net result is a rate of sludge accumulation of much lower than that of other processes.

User Friendly

There is no need for operators to come into contact with sewage at any time.

FAST units are more compact

FAST® is truly a state of the art process. Operating weight is less than half that of comparable biological units.

FAST handles the entire range of shipboard applications

The smallest FAST units are sized to handle harbor tugs and individual homes. The biggest systems so far handle 195,000 gpd from 1,750 persons aboard a cruise ship and 1,500,000 gpd from a municipal system at Tokoroa, New Zealand.

FAST units are built to last

Steel tanks are designed to meet ABS Deep Tank standards. This provides a strong foundation for a superior coating system. Many FAST units remain in everyday marine and offshore service after 30 years of continuous operation. When requirements change, these units can be and are updated at minimal cost.

FAST units can be upgraded

With such long service lives, older FAST units can be and are upgraded to meet the latest regulations when so required. Although the process technology is state of the art, the components are simple and economical.

All claims for the FAST process and for FAST sewage treatment systems are supported by more than 70,000 installations worldwide and over 40 years of research, development and real world operating experience.

New Certifications

New Certifications

The MarineFAST® technology utilizes a unique hybrid method of fixed and submerged treatment processes to both effectively treat wastewater and provide a system for management of biosolids. the treated effluent disinfection methods involve chlorination, chlorination/dechlorination, and now peracetic acid.

Scienco/FAST has been awarded USCG and Transport Canada certifications for our MARPOL configuration FAST systems using peracetic acid (PAA) as the disinfectant.

As a disinfectant, PAA is as effective or more effective than chlorine. PAA consumption should be about one-third that for sodium hypochlorite laundry bleach.

At the same time, PAA has no adverse environmental impact as chlorine does. There are no carcinogenic or mutagenic byproducts and PAA is fully approved by EPA for disinfection of sewage treatment system effluent.

We are now able to offer two alternate versions of every standard FAST MARPOL certified unit, (a) with chlorine disinfection and (b) with PAA disinfection. In addition, the use of PAA simplifies and substantially reduces the cost of our MARPOL certified FAST systems.

It represents a genuine improvement in many ways. PAA is available from Solvay Chemical and other suppliers and we will be stocking suitably sized containers for our customers.

Marine sanitation treatment systems treat sewage from offshore work applications and help lessen the environmental impact of contaminants.

MarineFAST® sewage treatment systems are also certified by the US Coast Guard’s USCG and International Maritime Organization’s MEPC.159 (55) effluent standards. As an effective marine sanitation device, the MarineFAST® adheres to the highest standards in the marketplace and versatile to fit in any configuration and size of vessels and offshore platforms. See more FAST® Certifications here.

Typically, the certification process involves thorough testing of how the system handles shock and vibration in the most extreme environmental standards such as above and beyond IMO requirements.

Material and equipment are key in meeting practical and regulatory sewage treatment requirements…

Material and equipment are key in meeting practical and regulatory sewage treatment requirements…

~ Author: Mr. Alan Fleischer, Corporate Director Marine Sales & Engineering

Mr. Fleischer holds a bachelor of science in aeronautical engineering from Parks Air College and a master of business administration with a special award for outstanding achievement in economics from St. Louis University. In 1973, he started the Marine Sewage Division for St. Louis Shipbuilding and Steel, itself a division of Pott Industries, lnc. St. Louis Ship’s Marine Sewage Division was acquired by the original developer of the FAST process technology, Smith & Loveless, Inc., a manufacturer of sewage transfer and treatment systems. Now designated [as] the Scienco/FAST division, it continues to operate as part of Bio-Microbics, Inc., which is in its own right a manufacturer and international supplier of sewage treatment systems and associated product lines.

Read about it by clicking here.

Project Portfolio Book

Scienco/FAST Marine Sanitation, Water, Wastewater, Sewage Project Portfolio Book

SciencoFAST Marine Sanitation, Water, Wastewater, Sewage Project Portfolio Book from Welcome to Bio-Microbics

Innovation has always been the core of Scienco/FAST. Decades of experience has taught us that our pre-engineered, modular components provide good installations aboard vessels and platforms of all types. The company continues to expand its product offering to include other transfer, treatment devices, and components for a multitude of applications, nitrogen reduction, oil/water separators, grease removal, membranes, renovations, aeration and mixing, biological tablets, and various other screening/filtration devices.

As world leaders in the on-site wastewater treatment markets, Bio-Microbics and Scienco/FAST provide advanced technology for wastewater, stormwater, and water treatment industries. From its diverse past, Scienco/FAST has been a part of such influential companies as Morton Salt and Smith & Loveless, Inc.

Internationally recognized for quality products and top-notch field services, Scienco/FAST is a manufacturer specializing in marine sewage devices, biological tablets, and other industrial technologies. The origins of SCIENCO® & FAST® can be traced back to the 1940′s in St. Louis, MO.

We focus on systems with benefits: The Best Marine & Offshore systems available! Installed aboard towboats, tugs, offshore supply vessels, diving support vessels, semi-submersibles, offshore platforms, drill ships, crane barges, fireboats, pilot boats, shop and office barges, container ships, tankers, bulk carriers, research vessels, icebreakers, survey ships, school ships, river towboats, harbor tugs, cruise ships, float homes, etc.:

• Have ease of installation, operation, and maintenance

• Provide economic solutions that cannot be achieved with other product offerings

• Impact global interest to reuse water

• Can utilize incentives and credits to build green

• Continue to remain in high demand for long term benefits for the life of the vessel

• Provide a wide range of options for specific applications

• Email us your inquiry; we look forward to working with you!

Annex IV: Prevention of Pollution

Annex IV: Prevention of Pollution by Sewage from Ships

Annex IV aims to reduce the sanitary risk from “black water” (discharges containing human, animal and/or medical wastes) and “grey water” (waste water from showers, sinks, washing machines, etc.). The vessels have to carry an International Sewage Pollution Certificate which is usually issued for a period of five years and implies a periodical survey of the ship’s sanitation and piping systems.

The most advanced wastewater purification systems are biological reactors in which waste particles are broken down and consumed by bacteria. The reactor has a fixed-film media that provides surface on which to attach aerobic bacteria with an efficient aeration system to digest all the organic material, lesser bacteria, and viruses. Afterwards, the treated effluent is disinfected through means of chlorination (and dechlor with IMO systems), UV, or a PAA (Paracetic Acid) system.

Mighty Mike® Technical Aids

Mighty Mike® Technical Aids and MSDS Information

Environmentally-Friendly Detergents and Cleaners:

- Mighty Mike® Biodegradability Technical Information Report

- Mighty Mike® Tips and Directions for Use Information Report

- Mighty Mike® Laundry Detergent Technical Information Report

- Mighty Mike® Liquid Laundry Detergent MSDS

- Mighty Mike® All-Purpose Cleaner MSDS

- Mighty Mike® Marine Multi-Purpose Cleaner MSDS

Mighty Mike Maintenance Tablets & Products:

SMM #Maritime Conference & Exhibition for #shipbuilding #marinetechnology

SMM Hamburg’s International #Maritime Conference & Exhibition – Trade fair for #shipbuilding and #marinetechnology

Do you know that Bio-Microbics’ #marine division, Scienco/FAST, was at the recent SMM Hamburg’s International #Maritime Conference & Exhibition – Trade fair for #shipbuilding and #marinetechnology? Click the image to go to The MediTelegraph, Italian publication, interview with Bob Rebori.

See BioMicrobics & Scienco/FAST at upcoming Tradeshows

See BioMicrobics & Scienco/FAST at upcoming Tradeshows

BioMicrobics participates in more than 40 tradeshows and training events every year! Below is information about upcoming tradeshows BioMicrobics exhibits. Check back to see what shows we will be attending next month! Pleas follow our Facebook,Linkedin, Twitter, and/or Google+ postings of photos, videos, and updates at these events!

Scienco/FAST, a provider of wastewater treatment systems to the offshore market, will be exhibiting at the following tradeshows:

Be sure to stop by the Booth! If you would like a member of our Team to present at an event, contact us at sales@biomicrobics.com.

[VIDEO] Maritime Reporter TV Interview

Published on Sep 20, 2016

At the SMM 2016 in Hamburg, Germany, Maritime Reporter TV’s Greg Trauthwein, Editor and Associate Publisher of Maritime Reporter and Engineering News, interviews Robert (Bob) J. Rebori, President, BioMicrobics Scienco/FAST. Mr. Rebori discusses current market conditions and drivers for waste water handling systems.

Category

People & Blogs

License

Standard YouTube License

[/wptabcontent]

Black and Graywater: An overlooked environmental issue

Black and Graywater: An overlooked environmental issue

June 30, 2020 | Environment, Inland, News | Written by Heather Ervin

The company’s in-house, fabricated steel tanks are welded to ABS deep tank standards. (Credit: Scienco/FAST)

Scienco/FAST, a manufacturer of marine sewage devices (MSD) based in St. Louis, Mo., has installed nearly 5,000 of its MSD units aboard towboats, tugs, offshore supply vessels, diving support vessels, pilot boats, containerships, tankers, bulk carriers, cruise ships, and many more types of vessels all around the world. The company has more than 50 years of research, development and real-world operating history for water, wastewater, storm water, and graywater treatment.

Scienco/FAST has installed 5,000 of its MSD units aboard a variety of vessels.

Scienco/FAST’s parent company BioMicrobics located in Lenexa, Kan., and incorporated in 1996, specializes in land-based solutions and has more than 80,000 installs worldwide using the FAST (Fixed Activate Sludge Treatment) system in various applications from homes to small municipalities and public/private commercial properties.

Not only does the company deal with graywater sewage, it has also dived into blackwater solutions. Marine Log sat down with Robert Rebori, president of BioMicrobics Inc. and Scienco/FAST; Bob Millerbaugh, executive vice president, marine sales and marketing, Scienco/FAST; and Jennifer Cisneros, vice president of marketing, BioMicrobics Inc., to learn more about gray and blackwater, MSD solutions and what operators should know about these types of discharges.

Marine Log (ML): What exactly does “blackwater” and “graywater” refer to in terms of discharges from marine vessels?

Bob Millerbaugh (BM): Blackwater is sewage from toilet water and graywater is wastewater from sinks, showers, and laundry. There is also a third category of waste. This comes from the galley in the form of “ground food” either from a sink or the dishwasher that adds to mixture.

Jennifer Cisneros (JC): Another way to look at it is, blackwater contains organic material, often containing digested food (fecal matter), urine (ammonia), and undigested biological substances (food waste) that contain and attract bacteria. Graywater is lightly soiled water containing sediment, detergents, cleaners, soaps, and other biological and non-biological contaminants that end up down the drain from other water fixtures.

ML: Can you tell us a little about Scienco/FAST and its work with black and graywater systems for maritime?

JC: Looking back at the FAST system’s history and experience, it goes back to the very first prototype of the marine FAST system was installed aboard the river towboat M/V Missouri in 1969. It all started when the St. Louis Ship Company was approached to develop a marine wastewater treatment device that would allow onboard wastewater to be reused for toilet flushing. Through a collaboration with the original inventor and the University of Kansas, the inception of an aerobic, wastewater treatment system that utilizes a completely submerged, fixed-film process with a passive recycle system without pumped recirculation or drying of the bacterial growth on the media was born–the FAST system.

After the first few years of successful operation on several vessels, the FAST unit sales and production began in 1973. Even though there were no federal rules before 1975 and the Clean Water Act had just been enacted, the towboats operating on U.S. inland rivers had to meet individual and varying state regulations. As such, the U.S. Coast Guard issued the first MSD requirements, in 33 CFR Part 159. All MSD systems must meet the minimum standards for 150 TSS, 200 fecal, certified by U.S. Coast Guard installed aboard vessels and are not subject to effluent sampling in service, which isn’t required by regulations. Official testing for the MarineFAST system was done aboard the towboat M/V United States and the FAST unit passed all tests to obtained Coast Guard certification.

After years of success and continuous performance of the systems throughout the ’80s, ’90s and 2000s, a production of the MarineFAST (Model L-3X) passed all tests specified by Navigation and Vessel Inspection Circular (NVIC) No. 01-09, including but not limited to IMO Resolution MEPC.159 (55) with results every bit as outstanding as those achieved in 1978. In addition, all standard and custom MarineFAST models are certified under Regulations for the Prevention of Pollution from Ships and for Dangerous Chemicals (SQR/2007-86) and MEPC.227 (64) using either chlorine or peracetic acid (PAA) disinfection. PAA is environmentally friendly and does not produce harmful byproducts. Also, use of PAA substantially reduced the cost of MARPOL certified FAST units.

BM: With these years of experience, we are an original equipment manufacturer that provides solutions in the global wastewater markets. Our focus on the system starts with a commitment to the project from consulting with our clients during the system design phase to ensure safe and efficient operation of equipment over time. We provide CAD services and tailor the manual to the specific needs of the system for proper maintenance and operation to ensure years of reliable service. As a matter of fact, some of our first FAST systems made are still in service and the average life span is 30-plus years. Scienco/FAST takes care of its customers’ maintenance, repair, and parts requirements, while also offering a full, after sales support service. This includes servicing, planned preventative maintenance, operator training and spares. Onsite repair service is also available through engineering and/or associate representative companies. Training can be provided either at client’s site or at our factory, where we cover all aspects of operation and maintenance.

Robert Rebori (RR): Additionally, each model size has a given rating based on the number of persons contributing to blackwater. When we add graywater and/or galley water (food waste water), we de-rate the number of persons for each model size based on the additional hydraulic and biological loads.

ML: What are the top regulatory concerns for black and graywater faced by today’s operators?

BM: The top concerns are new state-by-state regulations that are over and above the current federal regulations. These newer regulations reduce the effluent output limits. In some areas, such as the Great Lakes and Alaska, graywater discharge is treated the same as blackwater discharge.

ML: Any guess on how these regulations will develop over the next several years?

BM: We expect to see stiffer regulations, including the addition of regulations concerning treated graywater discharge in all areas of the U.S., as well as testing the effluent.

RR: A big concern is whether vessels that have blackwater-only MSD systems will be “grandfathered” into compliance or whether they will need to reconfigure their MSDs and piping in the future to add graywater treatment. In many cases, it could be expensive to modify the vessels, which would include loss of service for the vessel in port, or worse, in dry dock.

ML: How do regulations on this topic differ domestically compared to the rest of the world?

BM: The U.S. has regulations with the Clean Water Act, which was enacted in 1973. In other parts of the world, the standards of effluent discharge are stricter, and they sample the discharge. They also can’t discharge chlorine into waters. So, they have to add a de-chlorination system or use an alternative, such as peracetic acid. Scienco/FAST provides all of this equipment.

RR: Also, the differences in regulations vary based on environmental concerns, such as on the Alaska Waterways or the Great Lakes.

ML: Scienco/FAST is an international company. Can you talk about your work outside of the United States?

BM: We sell our systems to international companies, cruise lines, and to other countries navies and coast guards all over the world.

RR: And really, this could be a topic all its own. Most countries have ratified the IMO standards under MARPOL for the latest MSD requirements. However, enforcement ranges from none to complete enforcement. Also, many vessels are flagged in low-cost countries for vessel registration and they may not have the desire or the resources to enforce requirements. However, if vessel operators know they will be sailing to countries that do enforce the requirements, they will do the minimum to have the MSD with the Certificate for Inspected Vessels.

JC: As a global manufacturer of integrated water solutions, BioMicrobics is well versed in advanced wastewater, water, graywater and storm water treatment systems. Adopting new “integrated water management” technologies and innovations will lead us to rethink our relationship with water and how we can better manage it.

ML: How many units have you installed on vessels to date, and what types of vessels do you work with the most?

BM: We have approximately 4,700 systems aboard vessels, platforms and shore docks. Our core business is tug and towboats, however, with a full engineering and design staff, we can engineer systems for large cruise ships and even aircraft carriers.

RR: The answer to this also varies with economics. For instance, there is an abundance of bulk ore carriers and the price of oil is down, so those vessels and the offshore markets are down. Tug and towboats are up, and until recently, ferries, cruise vessels, research vessels, and military vessels were up. Essentially, we have thousands of systems operating everywhere around the world on all types of inspected vessels, including yachts, offshore platforms and supply vessels, and we will likely see growth in wind energy platforms.

JC: With so many vessel installs and over 80,000 land installations in more than 80 countries, the FAST process has become the most accepted method for treating sewage and maintaining public health by creating a better approach to sanitation management.

ML: You mentioned earlier that graywater is treated as sewage in the Great Lakes. Is this unique to that area, and if so, how come?

BM: It is unique to the area mostly due to the proximity of Canada, where the effluent standards are higher, as well as the large coastline that touches so many different states, each with protected areas.

RR: Environmentally, the fresh water in the Great Lakes can be more affected by the soaps and things in graywater than, say, oceans or even rivers with high-flow through.

________________________________________________